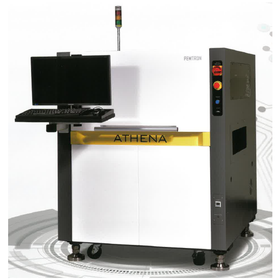

Introduction to Printed Circuit Board Appearance Inspection Equipment (Contract Manufacturing)

Here is a list of specifications and equipment for the 3D appearance inspection device for printed circuit boards.

Hamamatsu Pulse handles everything from small-lot, multi-variety printed circuit board assembly to finished product assembly and packaging, and has established a system that allows for consistent product provision centered around production outsourcing. ◆ Line Name: 3D-AOI Visual Inspection Device: VT-S530 (Omron) ◆ Target Board Dimensions: 50(W)×50(L) to 680×510mm ◆ Inspection Targets: Missing parts/Position deviation/Polarity/Un-soldered/Shorts/Solder shape ◆ Target Component Height: Up to 50mm *For details, please download and view the materials.

- Company:浜松パルス 都田工場

- Price:Other